How EMS Converts a Prototype Into Mass-Scale Production

6th December, 2025 Posted by Ankush Agrawal

Thomas Alva Edison once said, "Anything that won't sell, I don't want to invent. Its sale is proof of utility, and utility is success." Innovation is all about identifying a problem and finding a solution in the form of a product. A prototype is the refined version of that idea, created to test the concept in real market conditions. But innovation holds no value if it doesn't reach its target audience. This is where EMS comes into play, enabling your idea to reach every household through mass production.

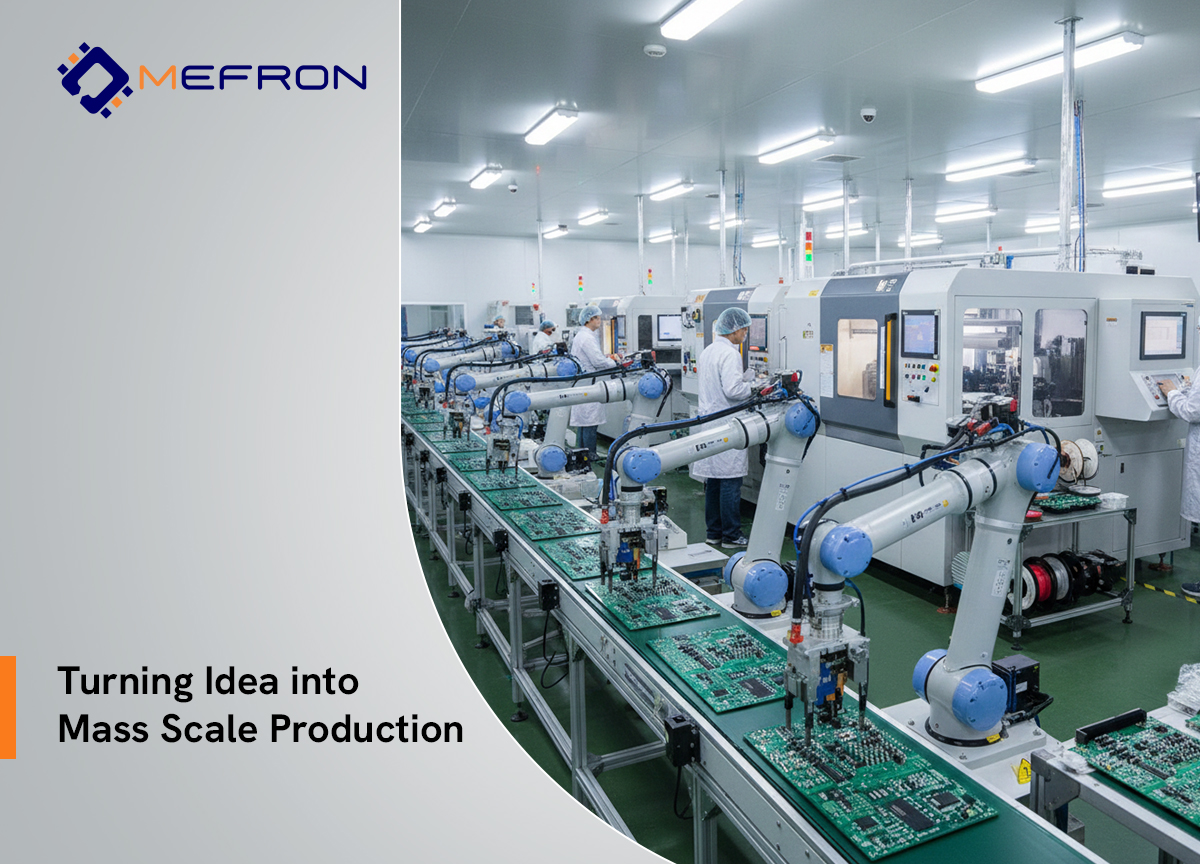

Electronic Manufacturing Services specialize in developing processes that integrate people, machinery, and materials to consistently produce the same product with accuracy and precision. That's why EMS serves as a strong partner for startups or OEMs who have an idea but lack the experience or investment required for mass manufacturing. In this blog, we will explore why OEMs need to partner with EMS for large-scale production.

6 Ways Through Which EMS Converts Prototype into Mass Scale Production

1. Design for Manufacturability (DFM)

In simple terms, Design for Manufacturability is the process of validating a prototype for mass-scale production. EMS engineers assess a prototype on several aspects:

- PCB layout for automated assembly

- Component placement for SMT feasibility

- Mechanical fit for tooling and fixtures

- Thermal and electrical performance

Once the product is approved on these aspects, the EMS team can ensure that every unit produced is accurate in terms of functionality, aesthetics, and overall quality. Design for manufacturability is a must to minimize defects and achieve Six Sigma standards in production.

2. Component Feasibility & Supply-Chain Optimization

What differentiates an electronic product from a non-electronic one is the assembled PCB and the network of wires. Even the smallest PCB consists of multiple components, and each component type varies in terms of dimensions, specifications, and functionality.

To streamline the manufacturing process, an EMS company works with multiple component vendors located across the globe. The challenge is to source the right-quality components on time and at the most competitive price, which makes inbound supply chain management complex.

Therefore, an EMS partner especially deals in PCB assembly services must identify reliable vendors, ensure component feasibility for the equipment, and maintain an efficient supply chain to support long-term production continuity while protecting OEMs from shortages or sudden cost spikes.

Looking for an EMS Partner for Scaling

3. Documentation Required by the EMS Company

As we discuss in the introduction of the blog, that all the units produced by the EMS should be homogenous, which means it is impossible to find a miniscule dissimilarity between two units. It could be possible only when every minute detail is documented in a proper format.

There are several files used for documenting a product which describe in detail what raw materials or components to be used in the product, in what quantity and dimensions they are going to use. There are files which define how the electricity flows on PCB and the files that show the accurate layout of the product.

Below is the list of documents that is required by an EMS Company:-

- BOM ( Bill of Materials) - List out all the components required with quantity and dimensions.

- Gerber Files - A complete drawing file of an assembled PCB with marking of components and traces.

- Firmware files and revision logs - How the device will function, interact with other components, and process inputs.

- Mechanical CAD - A computer aided design software file that shows the design.

- QC Parameters - A digital file that lists all the quality control checks, limits, and conditions.

4. Pilot Production & Validation

Even after meeting all the above parameters, there is still a possibility of minor errors. To build a robust and repeatable manufacturing process, EMS companies conduct pilot production and validation runs. This stage ensures that every unit reaching the end customer performs exactly as the OEM intends. Since the performance of each product directly impacts the OEM's brand value, EMS companies invest heavily in this stage.

India's Leading EMS Companies

Key activities in pilot production and validation include:

- Line setup

- Machine programming

- Assembly flow verification

- Functional testing

- Yield performance assessment

5. Mass-Scale Production Setup

At this stage, both the EMS and the OEM gain full confidence to begin mass production. The focus now shifts to setting up the most critical element of manufacturing, the machines. The EMS configures the SMT and THT production lines so that most operations run automatically with minimal human intervention. Along with this, they also install testing equipment required to verify the accuracy and performance of every electronic unit.

Next, the EMS establishes a structured process for long-term, high-volume production. Below is a concise list of the key setups involved:

- Automated SMT/THT production lines

- AOI, ICT, and functional testing systems

- Quality monitoring and control systems

- Packaging, branding, and finishing processes

- Traceability systems and batch control

This setup ensures that every unit produced meets the required specifications consistently and supports large-scale, uninterrupted production.

6. Private Labelling by an EMS Company

EMS not only manufactures the product but is also capable of packaging the product and delivering it to the final location where OEMs can sell it to the ultimate consumer. Through private labelling, an EMS takes the entire burden off the OEM across the production cycle, from manufacturing to final delivery.

OEMs only need to focus on innovation and marketing to capture market share, while the rest is handled by the EMS. EMS acts as a strong support system for the manufacturing sector in any economy because it enables the growth of both startups and large OEMs.

Conclusion

Scaling a product from a prototype to mass production requires the seamless integration of people, materials, machines, and methods within a controlled environment. This ensures that every product delivered to the end consumer meets the highest standards of quality. Scaling is not simply about copying a prototype; it involves developing an entire manufacturing setup capable of producing consistent products over the long term, while allowing for iterative improvements based on market demand.

Achieving this requires not only investment but also high levels of expertise and experience from the EMS partner. Startups can develop innovative prototypes and assess market demand, but turning those prototypes into commercially viable products is possible only through a trusted EMS partner like Mefron Technologies.

A strong network of EMS companies not only enables scalable production but also serves as an essential support system for young entrepreneurs aiming to launch electronics-based startups but can't think of developing in-house setup. In this way, EMS acts as a reliable, behind-the-scenes partner, empowering innovation and growth in the manufacturing ecosystem.