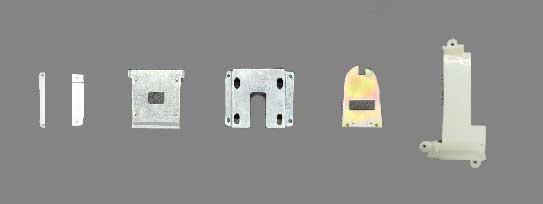

Unleash the Possibilities of Metal Sheets, with Our Sheet Metal Fabrication Expertise

Mefron's in-house facilities can design metal sheets and fabricate product-supporting accessories. We have partnered with a specialized tool house to provide the highest-quality and most cost-effective enclosures and accessories as quickly as possible in order to achieve the greatest product quality and customer satisfaction in sheet metal fabrication.

No matter the size or complexity of your project, our state-of-the-art equipment allows us to handle it with ease. From prototypes to large production runs, we are equipped to meet your needs.

Quick tooling development

Pilot production support

Surface treatment: plating, powder coating & painting

Design & engineering for manufacturability feasibility

Experts in providing customized and exclusive Metal enclosures

Quick prototype building by using different advanced technologies like laser and CNC etc