Accelerate Your Electronic Startup With Mefron's Box Build Infrastructure

1 October, 2025 Posted by Ankush Agrawal

At some point, many of us imagine a groundbreaking idea, one that could change lives or even disrupt an entire industry. Yet only a small percentage of these ideas ever reach the market. While lack of persistence can be a reason, many concepts fail simply due to the absence of proper infrastructure and manufacturing support.

Even highly skilled technocrats who manage to build a prototype often face challenges scaling production. This is where an EMS company with capabilities in Box Build Assembly Services becomes essential.

For startups, box build electronics manufacturers can help you with faster product realization. These manufacturers offer a complete production framework such as PCB assembly, electro-mechanical parts production, testing, and final assembly so innovators can focus on product design and refinements.

Understanding Box Build Assembly and Its Complexity

Box build assembly involves integrating PCBs, wire harnesses, enclosures, firmware, and packaging into a final product. It's more than just PCB assembly, it's a multi-disciplinary process that requires precision coordination and compliance with quality standards.

Manufacturing of electronics requires expertise and high-tech machinery including SMT lines, tooling, wire processing, metal fabrication, injection moulding machines and finally assembling them.

Curious to Know More About Box Build Assembly Process

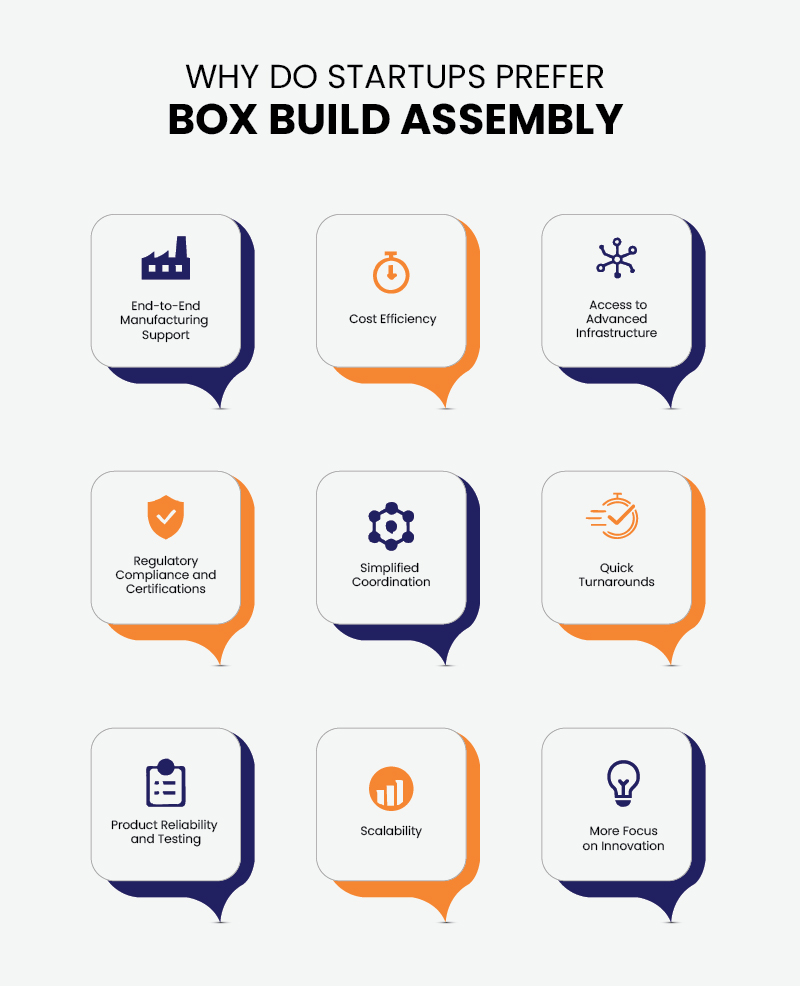

Why Do Startups Prefer Box Build Assembly?

1. End-to-End Manufacturing Support

Startups benefit from a consolidated production process, covering everything from PCB assembly and wiring to mechanical enclosure and packaging. This reduces the burden of working with multiple vendors, helping startups:

- Avoid capital-intensive infrastructure

- Focus on design and innovation

- Accelerate product launch timelines

2. Faster Time to Market

An experienced EMS company ensures that procurement, production, and quality control are managed without delay. This coordinated approach allows for:

- Quicker design iterations

- Smooth transition from prototype to mass production

- Faster product availability in the market

3. Cost Efficiency

Instead of investing in equipment and skilled labor, startups can leverage the infrastructure of an EMS company. Benefits include:

- Lower upfront investment

- Pay-as-you-scale models

- Optimized operations for better unit economics

4. Access to Advanced Infrastructure

Through partnerships with EMS providers, startups gain immediate access to:

- A highly trained and skilled workforce which can manage the electronics production seamlessly.

- Hi-tech machinery different stages of electronics production

These Box Build Assembly Solutions improve accuracy and repeatability across production.

5. Quick Turnarounds

Startups working with established EMS partners also get benefitted in areas like sourcing, vendor coordination, and logistics which ultimately helps for quicker turnarounds. Mefron, for instance, has sourcing centers in India, Singapore and China and has a huge supplier base across the globe for the procurement of electronic components.

6. Regulatory Compliance and Certifications

Reliable EMS providers ensure that every product meets the required compliance benchmarks such as:

- ISO certifications

- RoHS and CE compliance

- Safety testing and traceability

7. Scalability

From small prototype batches to full-scale manufacturing, EMS firms offer flexible production options, allowing startups to scale without delays or extra infrastructure.

8. Simplified Coordination

Working with one partner instead of many reduces communication gaps. This helps:

- Maintain design integrity

- Speed up decision-making

- Minimize logistical challenges

9. More Focus on Innovation

By outsourcing the technical production aspects, startups can channel their efforts into:

- Product refinement and R&D

- Marketing and customer engagement

- Building a scalable business model

10. Product Reliability and Testing

Structured quality assurance processes ensure each unit is thoroughly tested. It ensures minimize returns and improving customer satisfaction.

Why Mefron is the Right Choice for Box Build Assembly

It's hard to find electronics manufacturers in India that provide complete box build assembly. Most of the EMS provide standalone services like wire harnessing, PCB assembly, or sheet metal fabrication. Mefron, however, offers all these under one roof-ensuring better coordination and faster production.

Mefron is backed by necessary industry certifications and a global supply chain network, ensuring consistent component availability, reduced downtime, and cost-effective procurement.

Despite being relatively young, Mefron has quickly gained trust among startups and OEMs alike. Our reach spans across Automotive, IoT, Wearables, Medical, and Consumer Electronics-making us a reliable name among India's Best EMS Companies.

Connect with Mefron Sales Representative

Conclusion

India's journey toward becoming a global manufacturing hub depends on companies that can translate ideas into reality. EMS firms offering Box Build Assembly Solutions are at the forefront of this shift-enabling innovation, reducing time-to-market, and helping startups build scalable businesses.

Mefron, with its commitment to quality and growth, is actively contributing to the "Make in India" initiative. By enabling startups and OEMs to scale efficiently, Mefron is helping drive economic development and strengthen India's position in global manufacturing.