Electronic Manufacturing Services Provider In India

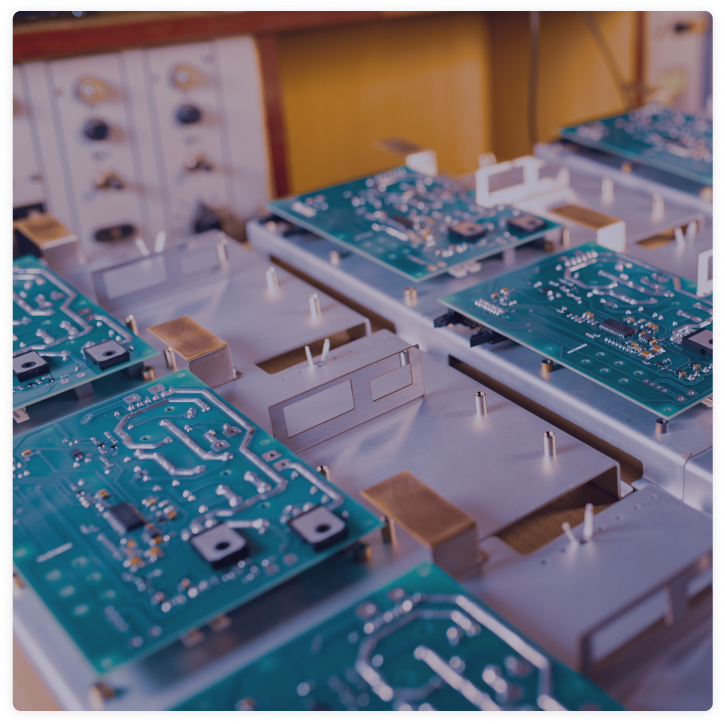

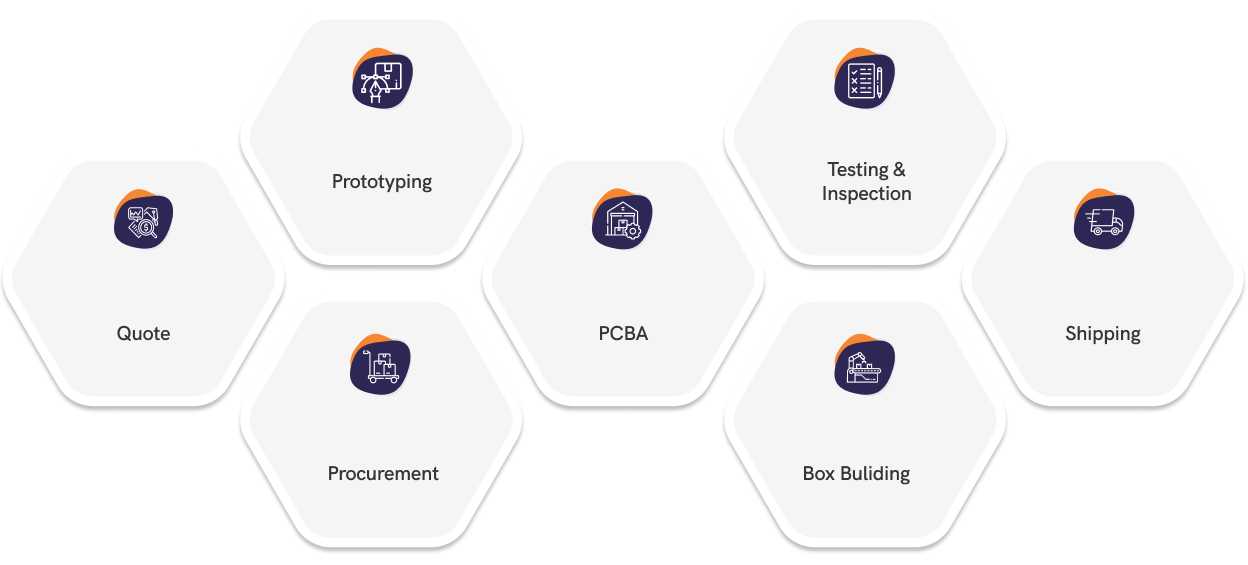

We serve Original Electronic Manufacturers (OEMs) with comprehensive electronic manufacturing services that bring their concepts and ideas to life. Our Ahmedabad facility is fully equipped with cutting-edge technology to help electronic manufacturers meet their goals of producing high-quality products while adhering to industry regulations. Mefron's production line can deliver a variety of electronic products for various industries with a minimum turnaround time and the highest quality.

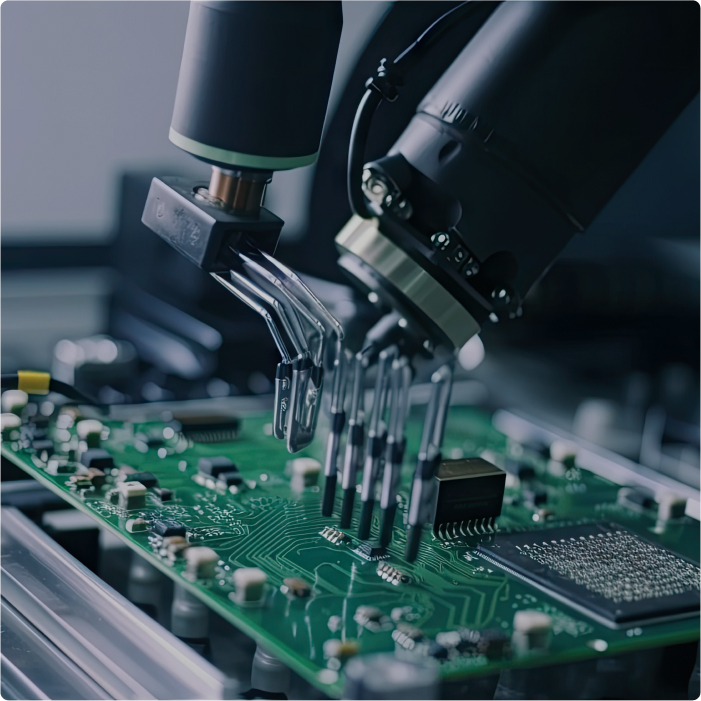

Most modern equipment, such as pick-and-place machines, SMT lines, wire harness techniques, high-accuracy paste printers, RoHS process-approved reflow, and an in-house IR-based BGA rework station, enable us to produce products of any complexity at flexible volumes.