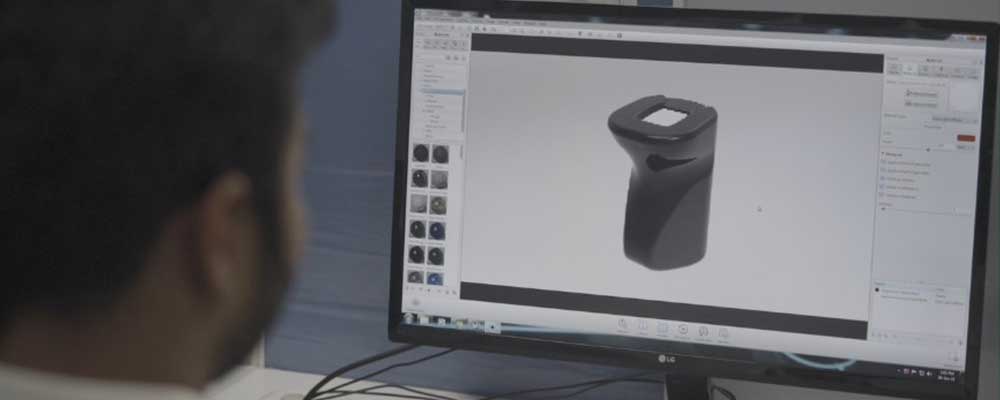

Designing & Manufacturing the shapes that fit your applications

Plastic injection molding is a versatile and increasingly valuable process that has applications in countless industries. Mefron's in-house, cutting-edge plastic molding machine meets all requirements and standards, including those for applications that demand the highest level of care, such as industrial and medical devices. Experts in our tool room and post-molding operations constantly keep an eye on to achieve our client's specifications and, at the same time, ensure the product comes out well-finished.